IR rework station

1. High success rate of repairing chips.

2. Simple and easy operation

3. Infrared heating. No damage to PCB and chip.

Leírás

IR rework station

1.IR BGA Rework Machine

IR in the name stands for "Infrared," which refers to the use of infrared heating. This type of heating provides

a more precise and controlled method of heating the PCB and its components, helping to reduce the risk of

damage to the board or components during the rework process.

The use of an IR rework station can help to improve the efficiency and accuracy of the PCB repair process,

and also helps to ensure that the repaired board meets industry standards for quality and reliability.

2.Product Features of Keyboard Video BGA Rework Machine

(1) Precise temperature control.

(2) High success rate of repairing chips.

(3)Two infrared heating areas increase temperature gradually.

(4)No damage to chip and PCB.

(5)CE certification guaranteed.

(6) Sound hint system: there is voice reminder 5s-10s before the completion of heating,to get the operator prepared.

(7) V-groove PCB works for rapid, convenient and accurate positioning, which can meet all kinds of PCB board of positioning.

(8) V-groove PCB works for rapid, convenient and accurate positioning, which can meet all kinds of PCB board of positioning.

3.Specification of Keyboard Video BGA Rework Machine

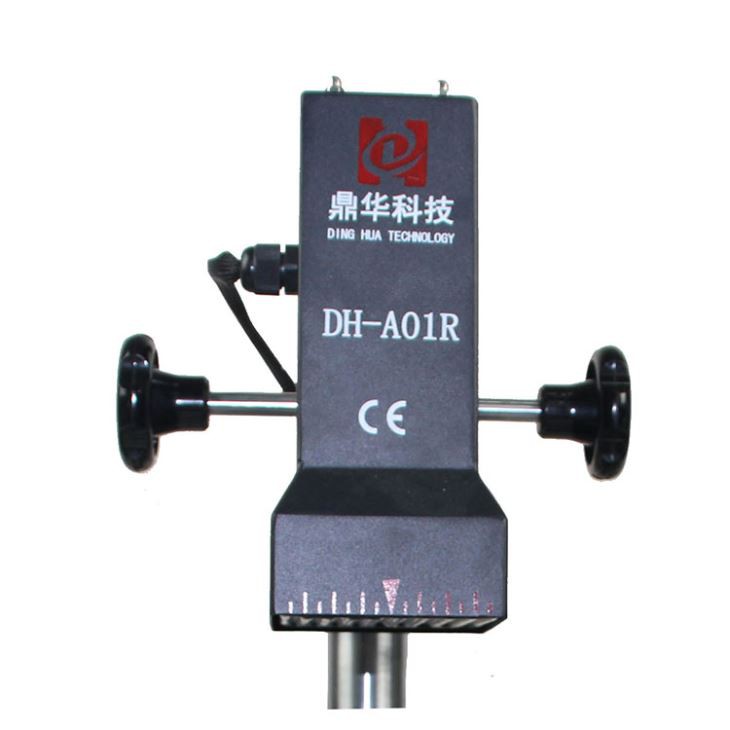

4.Details of Keyboard Video BGA Rework Machine

1. Two infrared heating zones ;

2.Led headlamp;

3.Dash board operating;

4.Limit bar.

5. Certificate of Keyboard Video BGA Rework Machine

6.Packing & Shipment of Keyboard Video BGA Rework Machine

7.Related knowledge

BGA cabling

When I place a BGA, the pad diameter is 0.35mm, and the center distance between two pads is 0.65mm. That is,

the size of 0.3 is enough to allow the trace to pass. I set the width of the trace to 0.1, and the safety margin is 0.1.

But how can we make it pass?my colleagues can follow me as usual, and ask where this is the problem

This will be easier to operate.

1) The grid point is set to 0.65mm or (0.65/2mm)

2) The origin is set to the center of this BGA, or one of the pads.

Then it's easy to grab the middle of the two pads.